PID control is used to adjust a controlled variable (e.g. pressure, temperature, frequency, etc.) to the setpoint. These PID controllers are of great importance for pump control, as they control the speed of the pump as an integrated component and thus enable automatic operation with all the resulting benefits.

How PID works

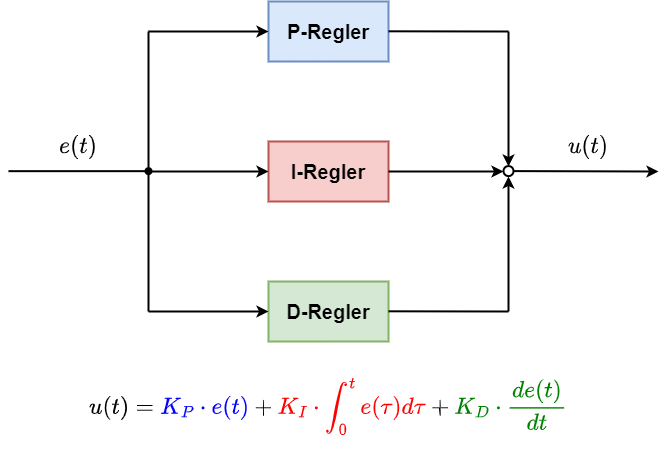

The PID controller uses three elements, the P element (proportional component), the I element (integral component) and the D element (differential component). The proportional component regulates based on the difference between the setpoint and actual value.

The closer the actual value approaches the setpoint, the lower the frequency of the pump is regulated. Theoretically, the target value is never reached. The integral component solves the problem of the actual value approaching the setpoint, but not reaching it, as the correction signal is large enough even with small differences between the setpoint and actual value. The integral part therefore integrates the difference.

The differential component briefly amplifies the signal of the difference between the actual and setpoint value so that the reaction of the controller is briefly accelerated. The D component is only recommended if the desired result is not achieved with PI control.

Universal controller

The PID controller is also known as a universal controller due to its wide range of applications and differentiated mode of operation. It can be adapted very well to different controlled systems and is therefore a solution for various challenges.

If all links are used, the PID controller is characterized by a fast response to differences (due to the D component), a targeted start-up (due to the P component) and precise control close to the setpoint (due to the I component). Management behavior is divided into three areas accordingly.