Ideal pump control for submersible motor pumps

The submersible motor pump is a multistage axial high-performance centrifugal pump that is installed vertically.

There are strict physical limits to the suction head of a pump: As the average pressure of the atmosphere at sea level corresponds to that of a 10 m water column, a suction head exceeding this 10 m is physically impossible, as the external pressure would then no longer be sufficient to force water into the pipe, so that a vacuum would form above the water column.

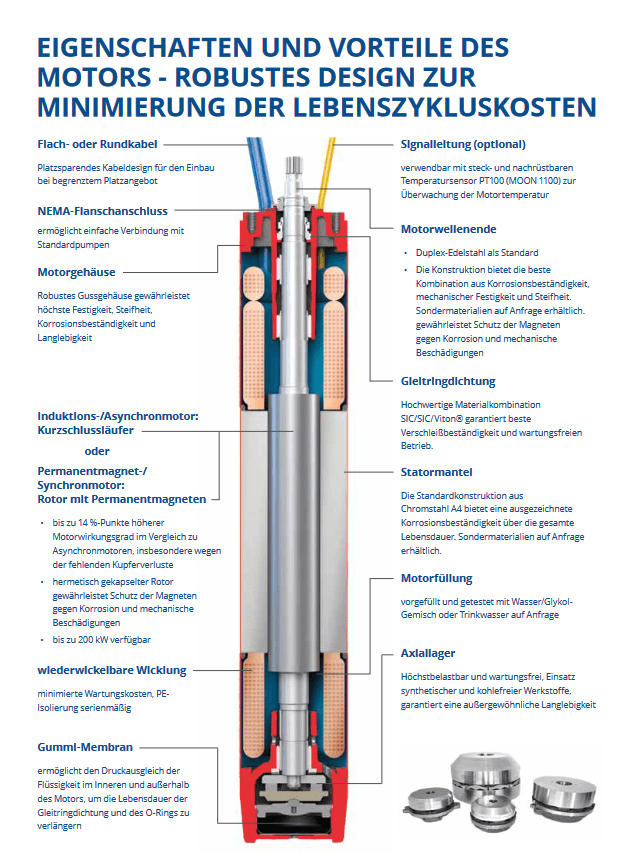

The image was provided with the permission of Pleuger Industries GmbH Friedrich-Ebert-Damm 105 D – 22047 Hamburg.

However, it is very time-consuming and inefficient to generate a vacuum at the inlet that is even close to this level, which is why water pumps are usually not able to do this at all, further limiting the possible intake height. In contrast, it is much easier to increase the pressure at the outlet because there is no hard physical upper limit for the pressure.

The problem can therefore be solved by the pump not drawing the water from the top of the deep well, but pushing it up from below. In order to achieve this efficiently, the submersible motor pump design was developed on the basis of the water-filled submersible motor, in which the drive motor is installed together with the water pump below the permanent water level and is surrounded by the water to be pumped and is itself filled with water (or another incompressible liquid). This design is therefore also referred to as a glandless pump. Due to the incompressibility of the filling medium, the pump motor can withstand even extreme external pressure and only requires a small diaphragm to compensate for thermal expansion. Because there is no need for a hermetic shaft seal between the motor and the pump, as would be the case with an air-filled motor, the term glandless pump has become established in the English-speaking world.

Submersible pumps are installed in wells, pipes, boreholes, shafts and basins. They are the most common type of pump for this application. In contrast to a submersible pump, which also works below the waterline, they are permanently installed. Submersible motor pumps are extremely scalable both in terms of diameter and the number of pump stages. They are therefore available in various standard sizes for pipes from 3 inches (DN80) as well as in extraordinarily powerful versions with several megawatts at flow rates of over 20000 m³/h or delivery heads of over 800m. They achieve a high level of efficiency as the water does not have to be sucked in.

The motor of a submersible motor pump is located below the pump stages and is cooled solely by the water flowing around it. Therefore, a minimum speed of usually 30 Hz is necessary to ensure sufficient flow for cooling. As the power of the pump depends on the frequency to the third power, this still results in a large control range of approx. 1:5. The pump controller should also monitor the water level to prevent the pump from running dry and overheating.

If possible, a sinusoidal filter must be installed in the pump control for submersible motor pumps, as shielded cables are generally not provided for these pumps. To protect the vertical bearings, ensure that a relatively short start-up time of approx. 5 seconds is selected for the control.